Concrete Machinery Maintenance: Essential Tips for Longevity

-

Thesis: Proactive, disciplined maintenance is non-negotiable for maximizing concrete machinery ROI, preventing costly downtime, and ensuring safety.

-

Structure:

-

The High Cost of Neglect: Downtime costs ($/hour), premature failure, safety hazards, voided warranties, reduced resale value.

-

The Maintenance Pyramid:

-

Daily Checks (Operator Level): Fluid levels (oil, coolant, hydraulics, fuel), leaks, tire pressure, wear parts (mixing blades, pump wear plates, trowel blades), cleanliness (WASH DOWN concrete!), safety systems (lights, horns, guards). Documentation.

-

Scheduled Servicing (Mechanic Level): Adhering strictly to OEM intervals for oil/filter changes, grease points (frequency and correct grease type), hydraulic system checks (filters, fluid condition), belt tension, electrical connections, calibration (sensors, scales).

-

Predictive Maintenance (Tech Level): Utilizing telemetry data (vibration, temperature, fluid analysis), regular inspections by trained techs for early signs of wear/cracks/corrosion.

-

Major Overhauls/Component Rebuilds: Planned replacement of major components (pumps, engines, hyd motors) based on hours/usage before catastrophic failure.

-

-

Critical System Focus (2025):

-

Hydraulics: Contamination is the #1 killer. Filter changes, fluid analysis, hose inspections. Emphasize cleanliness during service.

-

Electrical Systems (Especially EVs/Hybrids): High-voltage safety protocols, battery health monitoring, connector integrity checks. Software updates.

-

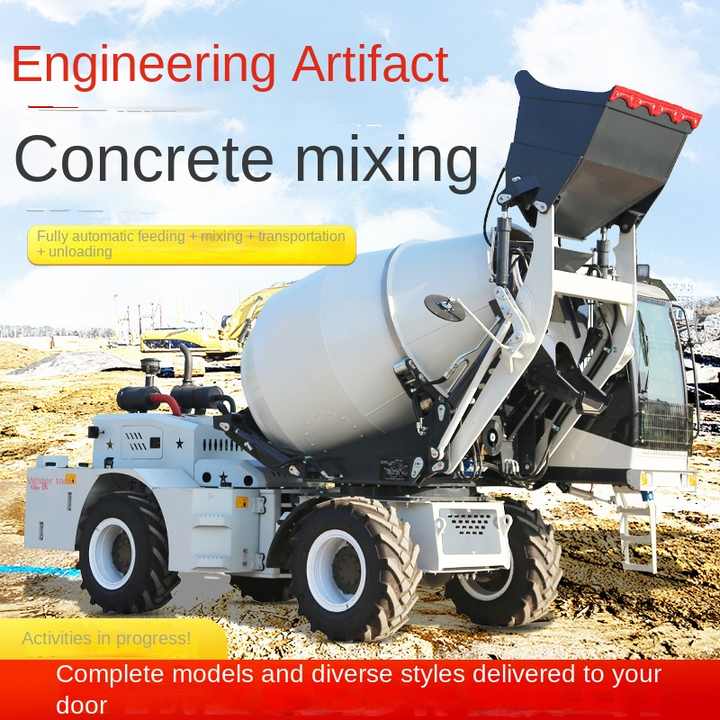

Mixing Systems: Blade wear, drum liner integrity, agitator seals. Calibration of water/addition systems.

-

Pumping Systems: Wear parts (pistons, cylinders, S-tubes, seals), pipe inspection/rotation, pressure testing.

-

-

Winterization/Storage: Proper cleaning (concrete removal!), fluid stabilization, battery maintenance, rust prevention, rodent protection. Critical for longevity.

-

Training & Culture: Empowering operators to do basic checks/report issues. Investing in mechanic training. Creating a culture where maintenance is prioritized over short-term production.

-

Leveraging Technology: Using CMMS (Computerized Maintenance Management Systems), telematics alerts, and diagnostic software to schedule and track maintenance efficiently.

-

Roll, Mix, Pour: Inside the Z

Roll, Mix, Pour: Inside the Z

High-Efficiency in Action: How

High-Efficiency in Action: How

Clean Lines, Smooth Pours: Zoo

Clean Lines, Smooth Pours: Zoo

Master the Flow: A Step-by-St

Master the Flow: A Step-by-St